Distillation

A bit of history

Today's lavender owes its fame to today's essential oil.

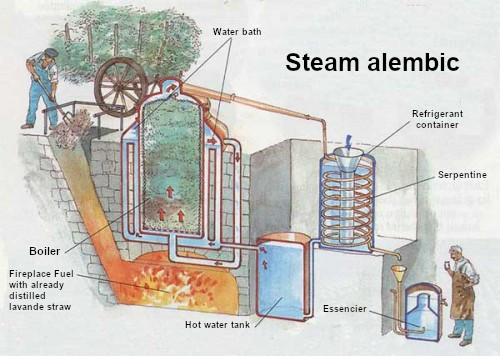

It is extracted from the plant by a very old technique, steam distillation.

This process was developed by the Arabs in the 6th century AD with the invention of the still. Today, the distillation equipment has been naturally perfected, but the operating principle remains the same overall.

The lavender flowers are placed on a grid at the bottom of the part of the alembic that is called the cucurbit.

The apparatus is put in contact with the steam of the water and it fills up with their essential oil as it passes through the flowers.

The distillation procedures have improved a lot over the years.

The open fire procedure

Based on this general principle, each manufacturer had a still suitable for his company. This material was made of copper, i.e. a metal that was easy to work, fairly light and a good heat conductor.

The essential part of the alembic consisted of a more or less large pot with a lid (hat) with a swan-neck extension that ends in a serpentine shape in a cooling vessel.

Steam alembic

Over the years the installations have been modernized, today's tanks contain on average between 5000 and 6000 liters, but the principle remains the same with steam formation.